|

Pages 1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

21 |

22 |

23 |

24 |

25 |

26 |

27 |

28 |

29 |

30 |

31 |

32 |

33 |

34 |

35 |

36 |

37 |

38 |

39 |

40 |

41 |

42 |

43 |

44 |

45 |

46 |

47 |

48 |

49 |

50 |

51 |

52 |

53 |

54 |

60 |

61 |

62 |

63 |

64

- Above:

The Concrete supplied by RMC

- Island Aggregates is poured to

line the shaft.

-

-

- Above:

With the shaft now complete

- a man hole for service access

has been installed

- Above:

Members of the project team unloading the

- restored shroud or rim segments into

the temporary workshop.

- The 4.5 tons of iron work was

transported back to the Island

- with the kind assistance of

Manx Independent Carriers.

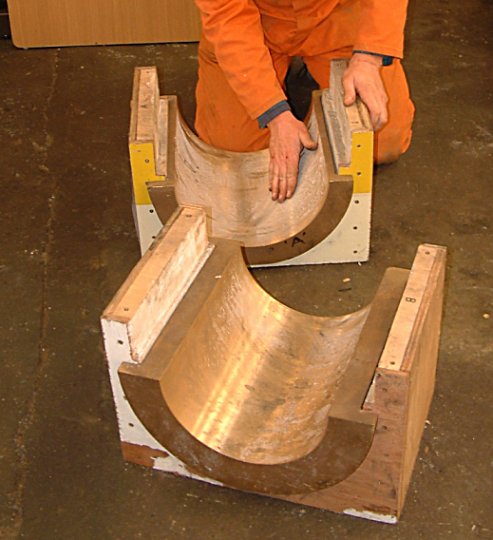

- Above:

The new phosphor bronze bearings on arrival at the workshop.

- The bearings have recently been

sat in the bearing blocks and are a perfect fit.

DECEMBER 2004

- Above:

The team start work on the wheel

-

pit base by fitting steel re-enforcing mesh and rebar.

- Above:

The steelwork is checked for level.The base

will form

- a concrete raft to support a column

against the river wall, which

- will also act as a load bearing

support for the bearing blocks and axle.

NEXT PAGE |