| |

Pages 1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

21 |

22 |

23 |

24 |

25 |

26 |

27 |

28 |

29 |

30 |

31 |

32 |

33 |

34 |

35 |

36 |

37 |

38 |

39 |

40 |

41 |

42 |

43 |

44 |

45 |

46 |

47 |

48 |

49 |

50 |

51 |

52 |

53 |

54 |

55 |

56 |

57 |

58 |

59 |

60 |

61 |

62 |

63 |

64

- Above:

Gerry Sweetmore, Commercial Pattern Shop Manager

- checking the measurements on the

new pattern.

-

-

-

- Above:

Paul Turner, mould maker holding the new

- pattern prior to the impression

being made in the sand.

- Above:

The mould now ready to received the cast.

- Above:

Foundry supervisor Roy Johnson and metal

caster

- Malcolm Web pour the white hot SG

grade iron into the moulds.

Above: Hot

gasses and flame leap out of the vent holes on the mould.

September 2004

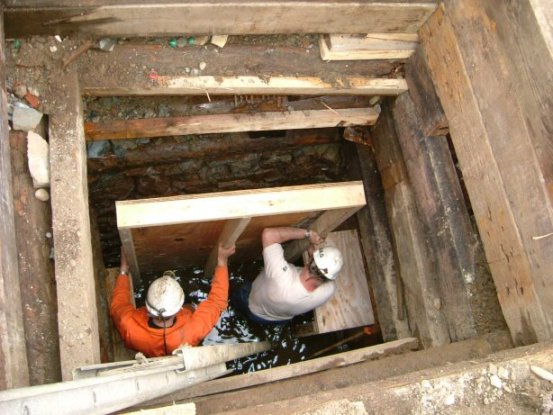

- Above: The complicated shuttering is installed

- in the access shaft on the three way junction.

NEXT PAGE |

|