| |

Pages 1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

21 |

22 |

23 |

24 |

25 |

26 |

27 |

28 |

29 |

30 |

31 |

32 |

33 |

34 |

35 |

36 |

37 |

38 |

39 |

40 |

41 |

42 |

43 |

44 |

45 |

46 |

47 |

48 |

49 |

50 |

51 |

52 |

53 |

54 |

55 |

56 |

57 |

58 |

59 |

60 |

61 |

62 |

63 |

64

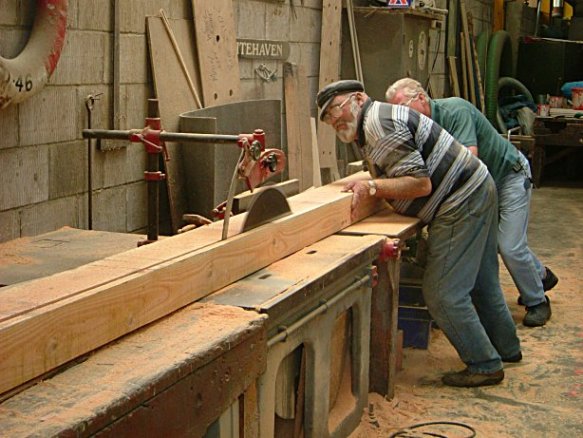

- Above:

One of the spokes being cut to the required taper to match

- the sockets on the hub and shroud

ends. Each spoke is cut to a finished

- length of 22 feet 6 and 3/8 of an

inch as it would have been by the Victorians.

-

-

- Above:

A pile of now completed spokes. All forty

were

- made in just over one week by the

Master Carpenters.

- Above:

Darren Hadley sandblasting one of the

massive seven foot diameter hubs.

- Roman numerals were found on each

of the twenty spoke sockets.

- Above:

Ramsey Shipyard's Craig Tinkler painting the hubs.

- Above:

The finished item. The hubs wouldn't have looked

- any better when they had

originally been made.

-

- Above:

Gareth Hughes, pattern maker at the

Progress Foundry in Stoke

-

- puts the finishing touches to the

wooden patterns for the

-

- reproduction of the shroud

sections of the wheel.

NEXT PAGE |

|